AUTOCLAVE MACHINE

EXPLAINATION

STRUCTURE

WORKING

TYPES

USING GUIDE

Introduction:

An autoclave is a specialized device used to sterilize equipment, instruments, and materials by applying high-pressure saturated steam. This process is critical in various industries such as healthcare, laboratories, and manufacturing to eliminate all forms of microbial life, including bacteria, viruses, fungi, and spores. Invented by Charles Chamberland in 1879, the autoclave has since become an indispensable tool in ensuring safety and sterility.

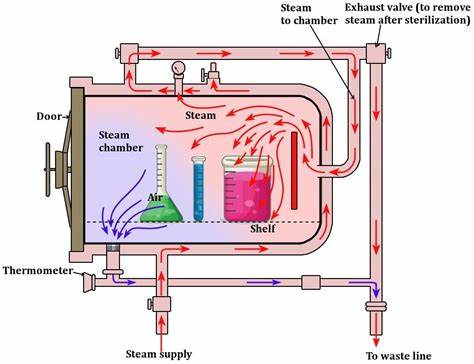

Structure of an Autoclave Machine

An autoclave typically consists of several key components designed to efficiently carry out the sterilization process. Below is an overview of its structure:

- Chamber: The main compartment where items to be sterilized are placed. It is usually made of stainless steel to withstand high pressure and temperature.

- Jacket: Surrounds the chamber and helps in preheating and maintaining temperature uniformity.

- Door: Equipped with safety locks to ensure it remains tightly sealed during operation.

- Control Panel: Allows users to set sterilization parameters such as temperature, pressure, and time.

- Steam Generator: Produces the saturated steam required for sterilization.

- Exhaust Valve: Releases air and steam from the chamber after the sterilization cycle.

- Pressure Gauge and Thermometer: Monitor the internal conditions of the chamber.

Types of Autoclave Machines

Autoclaves come in various designs tailored to specific applications. Below is a detailed note on the types of autoclave machines:

1. Gravity Displacement Autoclave

- Working Principle: Utilizes gravity to displace air within the chamber by introducing steam.

- Applications: Commonly used for sterilizing flat surgical instruments, utensils, and unwrapped items.

- Advantages: Simple operation and cost-effective.

- Limitations: Less effective for porous materials and complex loads.

2. Pre-Vacuum (High-Vacuum) Autoclave

- Working Principle: Air is evacuated from the chamber using a vacuum pump before steam is introduced.

- Applications: Ideal for sterilizing wrapped instruments, porous materials, and hollow items.

- Advantages: Ensures deep steam penetration for effective sterilization.

- Limitations: Higher initial cost and requires more maintenance.

3. Horizontal Autoclave

- Design: Features a horizontally oriented chamber.

- Applications: Commonly used in large laboratories, hospitals, and industrial settings.

- Advantages: Accommodates large loads and bulky equipment.

- Limitations: Requires more space compared to vertical autoclaves.

4. Vertical Autoclave

- Design: Compact with a vertically oriented chamber.

- Applications: Preferred in smaller clinics, research labs, and facilities with limited space.

- Advantages: Space-efficient and user-friendly.

- Limitations: Limited load capacity compared to horizontal models.

5. Class N Autoclave

- Working Principle: Operates without pre-vacuum functionality, relying on gravity displacement.

- Applications: Sterilizes non-porous items and simple instruments.

- Advantages: Cost-effective and easy to use.

- Limitations: Unsuitable for complex or porous loads.

6. Class B Autoclave

- Working Principle: Incorporates pre-vacuum cycles for enhanced air removal.

- Applications: Sterilizes a wide range of items, including porous and wrapped materials.

- Advantages: High sterilization efficiency.

- Limitations: Higher operational cost.

7. Portable Autoclave

- Design: Small, lightweight, and easy to transport.

- Applications: Used in field settings, small clinics, and mobile medical units.

- Advantages: Portable and cost-effective.

- Limitations: Limited sterilization capacity.

8. Double-Door (Pass-Through) Autoclave

- Design: Features two doors for separate loading and unloading areas.

- Applications: Used in cleanroom environments and pharmaceutical industries to prevent cross-contamination.

- Advantages: Maintains sterile environments and ensures workflow efficiency.

- Limitations: Expensive and requires significant installation space.

9. Laboratory Autoclave

Limitations: May require specialized training for operation.

Design: Specifically tailored for laboratory use, often with advanced programming options.

Applications: Sterilizes glassware, media, and laboratory waste.

Advantages: Versatile and supports research needs.

Working Principle of an Autoclave

The autoclave operates on the principle of moist heat sterilization, which effectively kills microorganisms by denaturing their proteins. The key factors that facilitate this process are:

- Steam: Acts as the sterilizing agent.

- Temperature: Typically set between 121°C and 134°C.

- Pressure: Maintained at around 15 to 30 psi to achieve high temperatures.

- Time: Varies based on the type of load, usually 15-30 minutes.

Step-by-Step Working Process

- Loading: Items are placed in the chamber on racks or trays, ensuring proper steam penetration.

- Air Removal: Air is expelled from the chamber using gravity or vacuum methods.

- Steam Injection: Saturated steam is introduced, filling the chamber and contacting all surfaces.

- Sterilization: The chamber maintains the set temperature and pressure for the designated time.

- Exhaust: Steam is vented out, and the pressure normalizes.

- Drying: Items are dried using residual heat or a vacuum pump.

- Unloading: Sterilized items are removed once cooled.

Uses of Autoclave Machines:

Autoclaves are employed across various fields, each serving specific purposes. Below is a detailed breakdown of their uses:

1. Healthcare Applications

- Sterilization of Surgical Instruments: Ensures surgical tools, forceps, scalpels, and other equipment are free from pathogens.

- Disinfection of Hospital Supplies: Includes gowns, drapes, and linens used in medical settings.

- Waste Management: Decontaminates biohazardous waste such as syringes, scalpels, and contaminated materials before disposal.

- Sterile Storage Preparation: Prepares medical items for long-term sterile storage.

2. Laboratory Applications

- Glassware and Equipment Sterilization: Sterilizes flasks, petri dishes, pipettes, and other reusable lab items.

- Culture Media Preparation: Ensures media used in microbiology and cell cultures is free of contaminants.

- Sterilization of Biological Waste: Neutralizes biohazardous waste before it is discarded.

- Decontamination of Samples: Treats potentially infectious samples to ensure safety.

3. Industrial Applications

- Pharmaceutical Manufacturing: Sterilizes drug containers, ampoules, and equipment involved in drug production.

- Food and Beverage Processing: Extends shelf life by sterilizing canned foods, beverages, and packaging materials.

- Rubber Vulcanization: Enhances the strength and elasticity of rubber products.

- Composite Curing: Used in the aerospace and automotive industries to cure composite materials under heat and pressure.

4. Veterinary Clinics

- Sterilization of Tools: Ensures surgical and diagnostic tools used in animal care are free from contaminants.

- Disinfection of Cages and Feeding Equipment: Maintains hygiene in animal shelters and research facilities.

- Pathogen Elimination: Decontaminates materials used in handling infectious diseases in animals.

5. Research and Development

- Biological Experiment Preparation: Supports sterile environments for experiments in genetics, biotechnology, and other sciences.

- Sterilization of Equipment: Ensures accurate results by eliminating contaminants from research equipment.

- Containment of Hazardous Materials: Safely neutralizes pathogens and hazardous substances used in experiments.

6. Food and Beverage Industry

- Packaging Sterilization: Ensures containers such as cans, bottles, and jars are sterile before filling.

- Food Preservation: Sterilizes foods under controlled heat to extend shelf life and ensure safety.

- Equipment Sterilization: Cleans and sterilizes processing machinery used in production lines.

7. Miscellaneous Applications

- Cosmetic Industry: Sterilizes tools and materials used in the production of makeup and skincare products.

- Tattoo Studios and Spas: Ensures that needles, forceps, and other tools are free from contamination.

- Educational Institutions: Provides sterilized equipment for practical lab sessions in schools and colleges.

Detailed Applications of Autoclave Machines

Autoclave machines serve a variety of detailed purposes across industries:

Healthcare

- Surgical Sterilization: Essential for ensuring that surgical tools and equipment are free of any contaminants, protecting both patients and medical staff.

- Sterile Supplies Preparation: Prepares items like bandages, syringes, and gowns for safe medical use.

- Waste Treatment: Safely neutralizes biohazardous waste, including contaminated sharps and medical disposables.

Laboratories

- Culture Media Preparation: Sterilizes growth media used in microbiology experiments to prevent contamination.

- Glassware Cleaning: Ensures that flasks, petri dishes, and pipettes are sterilized before use.

- Sample Decontamination: Decontaminates infectious materials before disposal.

Industrial Applications

- Composite Curing: Utilized in the aerospace and automotive industries for curing composite materials under heat and pressure.

- Pharmaceutical Production: Sterilizes drugs, packaging materials, and production equipment.

- Rubber Vulcanization: Enhances the physical properties of rubber through heat and pressure.

Veterinary Clinics

- Animal Care Equipment: Sterilizes surgical and diagnostic tools used in veterinary practices.

- Animal Facility Sterilization: Maintains the sterility of cages and feeding equipment in research and animal care facilities.

Food and Beverage Industry

- Packaging Sterilization: Ensures that cans, bottles, and other food packaging materials are free from microorganisms.

- Food Safety: Sterilizes food items in sealed containers to extend shelf life and ensure consumer safety.

- Equipment Sterilization: Used for cleaning and sterilizing processing machinery.

Research and Development

- Experimental Preparation: Supports sterile conditions for experiments in biotechnology and nanotechnology.

- Biocontainment: Ensures hazardous biological agents are deactivated before disposal.

Conclusion

The autoclave is a vital machine that combines science and engineering to ensure sterility and safety in critical environments. Its robust design, various types, and wide-ranging applications make it indispensable in modern industries. Understanding its working principles and proper usage is essential for achieving optimal sterilization outcomes.