BUNSEN BURNER

INTRODUCTION

STRUCTURE

TYPES

WORKING PRINCIPLE

The Bunsen Burner: A Detailed Overview

The Bunsen burner is a fundamental piece of laboratory equipment widely used for heating, sterilization, and combustion. Named after Robert Bunsen, a German chemist who refined its design in 1855, the Bunsen burner is a staple in educational and professional laboratories. Its versatility, simplicity, and efficiency make it indispensable for various scientific applications.

Introduction to the Bunsen Burner

A Bunsen burner is a gas-powered device that produces a single open flame. It is designed to provide a controllable and consistent heat source. The burner is fueled by natural gas (methane) or a liquefied petroleum gas (propane or butane). It is commonly used in chemistry, biology, and physics labs for heating substances, conducting experiments, and sterilizing equipment.

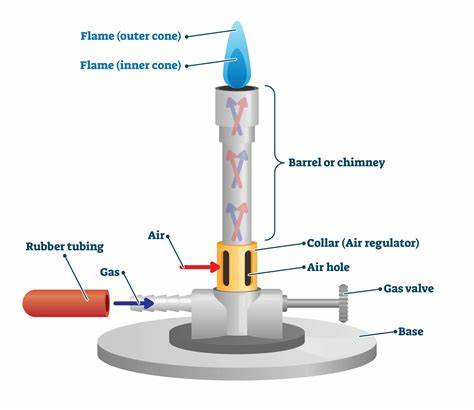

Structure of the Bunsen Burner

The Bunsen burner consists of several key components, each contributing to its functionality:

- Base: Provides stability and supports the burner.

- Gas Inlet: Connects the burner to a gas source, supplying fuel for combustion.

- Barrel (or Tube): A vertical metal tube where gas mixes with air before combustion.

- Collar: A rotating component at the base of the barrel that adjusts the air intake.

- Air Holes: Openings on the collar that control the amount of air mixed with gas.

- Nozzle (or Jet): Located at the base, it directs gas flow into the barrel.

- Flame: Produced at the top of the barrel when the gas-air mixture ignites.

Types of Bunsen Burners

Different types of Bunsen burners are available to cater to specific laboratory needs. These include:

1. Standard Bunsen Burner

- Description: The classic design with adjustable air holes to control the flame.

- Applications: General heating, combustion, and sterilization tasks in labs.

2. Tirrill Burner

- Description: Similar to the standard burner but includes an additional gas flow control valve.

- Applications: Provides precise flame control for sensitive experiments.

3. Meker-Fisher Burner

- Description: Produces a broader and hotter flame due to a grid at the top of the barrel.

- Applications: Suitable for high-temperature applications requiring even heat distribution.

4. Teclu Burner

- Description: Features a conical-shaped tube and enhanced air regulation.

- Applications: Ideal for achieving higher flame temperatures.

5. Micro Bunsen Burner

- Description: A compact version designed for micro-scale experiments.

- Applications: Used in small-scale research and educational settings.

Working Principle of the Bunsen Burner

The Bunsen burner operates on the principle of gas-air mixing to produce a flame suitable for various applications. Its working can be summarized as follows:

- Gas Supply: When the gas valve is opened, fuel flows into the burner through the gas inlet.

- Air Mixing: The collar is adjusted to allow air to mix with the gas inside the barrel. The air-gas ratio determines the flame’s characteristics.

- Ignition: A spark or lighter ignites the gas-air mixture at the top of the barrel, producing a flame.

- Flame Adjustment: By rotating the collar, the air intake can be controlled to produce either a luminous (yellow) flame or a non-luminous (blue) flame:

- Luminous Flame: Yellow and cooler due to incomplete combustion, suitable for low-temperature tasks.

- Non-Luminous Flame: Blue and hotter due to complete combustion, ideal for most laboratory applications.

Uses of the Bunsen Burner

The Bunsen burner serves a variety of purposes in laboratory settings, including:

- Heating: Used to heat liquids, solids, and solutions in beakers, test tubes, and crucibles.

- Sterilization: Effective for sterilizing needles, loops, and other small instruments.

- Combustion Experiments: Facilitates studies on combustion reactions and flame analysis.

- Boiling and Evaporation: Speeds up boiling and evaporation processes.

- Melting: Suitable for melting small quantities of substances like wax or metals.

Applications of the Bunsen Burner

Bunsen burners find extensive applications in educational, research, and industrial laboratories:

1. Chemistry Laboratories

- Chemical Reactions: Provides a controlled heat source for studying chemical reactions.

- Flame Tests: Used to identify metal ions based on the color of the flame.

- Synthesis: Assists in synthesizing compounds that require heat.

2. Biology Laboratories

- Sterilization: Ensures sterile conditions for microbiological work by sterilizing tools and creating sterile zones.

- Sample Preparation: Helps in preparing samples for microscopy or culturing.

3. Physics Laboratories

- Heat Transfer Studies: Facilitates experiments on conduction, convection, and radiation.

- Material Testing: Supports tests on thermal properties of materials.

4. Educational Institutions

- Practical Learning: Provides students with hands-on experience in heating and flame-based experiments.

5. Industrial Applications

- Glassblowing: Used in crafting and repairing laboratory glassware.

- Metalwork: Assists in small-scale metalworking and soldering tasks.

6. Forensic Science

- Sample Analysis: Aids in analyzing trace evidence by heating or burning samples.

Safety Precautions When Using a Bunsen Burner

While the Bunsen burner is a versatile tool, it must be used with caution to prevent accidents:

- Wear Protective Gear: Always wear safety goggles, gloves, and a lab coat.

- Inspect Equipment: Ensure the burner and gas connections are in good condition.

- Control the Flame: Adjust the flame to avoid overheating or accidents.

- Monitor Surroundings: Keep flammable materials away from the burner.

- Proper Ignition: Use a spark lighter or matchstick to ignite the burner safely.

- Turn Off Gas: Close the gas valve immediately after use.

Conclusion

The Bunsen burner remains a cornerstone of scientific experimentation, offering a reliable and efficient heat source. Its adaptability to various tasks, coupled with its straightforward design, makes it a must-have in any laboratory. Understanding its structure, types, uses, and safety measures ensures optimal performance and minimizes risks during operation.